As an industrial facility operator or business owner, it is important to keep your assets clean and free of contamination. That’s where industrial steel cleaning comes in – this specialized process is used to clean all types of metals, including those used in industrial equipment.

Industrial steel cleaning is a process used to clean and maintain steel surfaces. Once contaminated by oils, grease, varnish, or rust, industrial steel can quickly become unusable. Industrial steel cleaning includes both manual and mechanical methods of removing contaminants. You can also hop over here to know more about industrial steel cleaning.

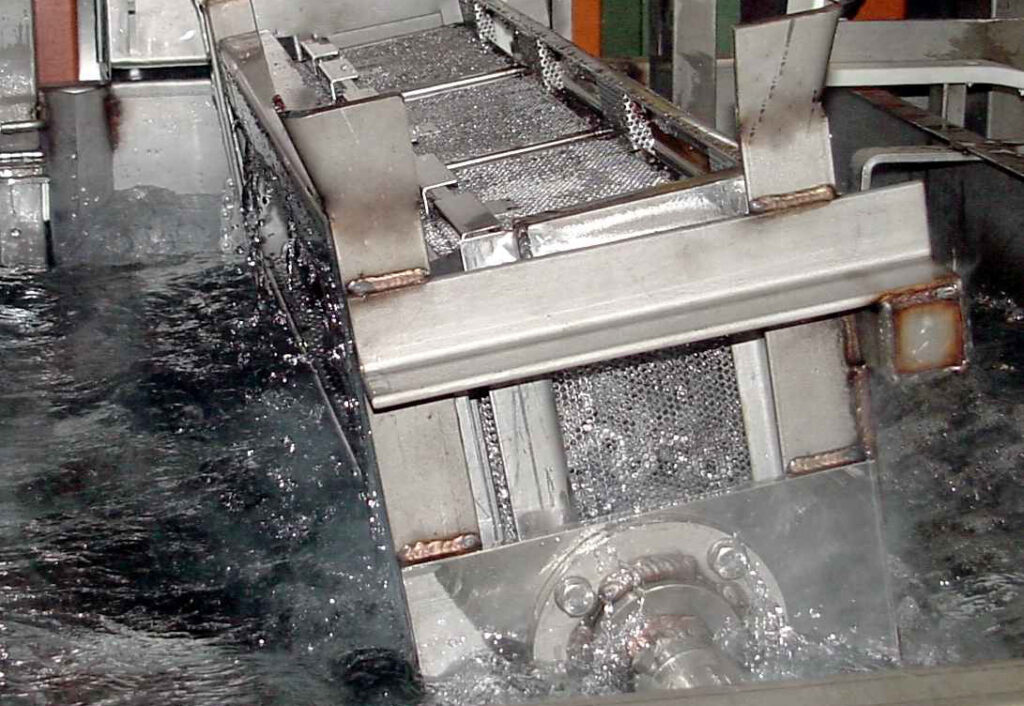

Image Source: Google

Manual methods typically involve using brushes, buckets, and sponges while mechanical methods use sandblasting, vibration, or heat to remove the contaminants. After being cleaned, industrial steel must be treated to prevent future contamination. Treatment can include applying a finish such as an epoxy paint or corrosion-resistant powder coating.

When it comes to industrial steel cleaning, there are many benefits that can be enjoyed. Industrial steel cleaning can help remove built-up contaminants and oils that can impair the performance of a steel object. Additionally, industrial steel cleaning can also improve the appearance of a metal item. Finally, industrial steel cleaning can also reduce the risk of corrosion in metal objects.

One of the primary benefits of industrial steel cleaning is that it can help remove built-up contaminants and oils that can impair the performance of a steel object. These contaminants can include residue from oil production, dirt, dust and other substances. By using industrial steel cleaning techniques, these contaminants and oils can be removed from the metal surface.